Equipment

Bargain Shopping

It might strike some as odd that in the high-stakes, high precision world of measuring grooves, the U.S. Golf Association has opted for a $150 digital scanner over a $175,000 machine capable of detecting surface roughness differences down to the millionth of a millimeter.

But in this case simpler (and cheaper) is just better.

With a condition of competition set to go into effect requiring players on the PGA Tour to use duller grooves starting in January, the USGA will need a highly portable, fast and efficient methodology for measuring grooves on irons and wedges. While the space-age Alicona InfiniteFocus 3D measuring device was used by the USGA to establish its baseline groove measurements, the USGA realized that the highly sensitive and ultra-expensive device might not be the most practical way to measure grooves at tournament sites.

Much like with the USGA's development of the Characteristic Time device, or pendulum tester, to measure the spring-like effect in driver faces, a portable alternative was developed to measure grooves in wedges and irons. And like with the CT tester, USGA senior research engineer Matt Pringle was the man behind the effort to simplify the complex measurements of groove depth, sharpness and cross-sectional area. The key came in realizing that portable flatbed scanners today are much more sophisticated than they need to be for making digital copies of photographs -- and just sophisticated enough for measuring grooves on clubfaces.

"The short answer is the Alicona device is a very sophisticated device that can do a whole lot more than measure grooves, but at the end of the day for most applications related to grooves, you don't need that," Pringle said. "You need a two-dimensional cross section of what's going on.

Pringle says a state-of-the-art $175 digital scanner sees 6,400 dots per inch. That means a resolution of .00015 of an inch, which, he says, "is certainly very adequate resolution for us."

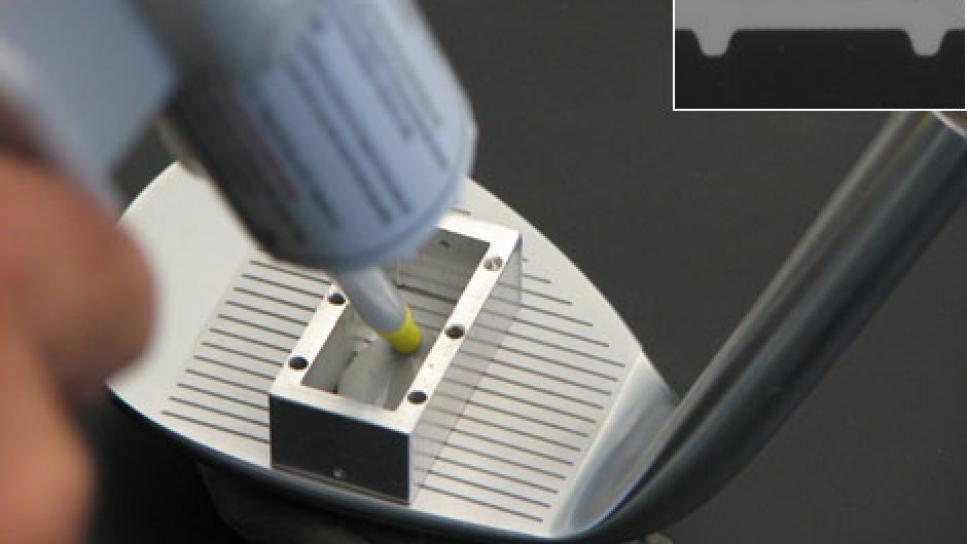

Pringle's novel solution also involved the use of a metallography replicating compound, or what technical folks might call "goo." Made by Microset Products Ltd. In Warwickshire, England, it's been used by structural engineers to analyze surface roughness and tiny cracks in metals.

In measuring the grooves on a clubface, the goo is squirted on to the face and works its way into the grooves. Once the compound sets, a second coating of the compound material is put on top of the first in a contrasting color and the resulting image shows the contour of the groove pattern. That slice of hardened goo is digitized on a scanner, and then is put through some sophisticated computer software that Pringle and his team developed.

"That material has been developed for exactly what we're trying to do: inspect small detailed metal parts," Pringle says.

Benoit Vincent, chief technical officer at TaylorMade, says the simplicity of the system is what makes it better than a machine that costs a thousand times more.

"It's portable, cheap, fast, low tech/easy to use and accurate enough at least to screen and even to rule when geometry is clearly in or out of conformance," he says. "As long as you can generate a 2D view of the groove contour, you can measure what you need."

Not only that, the simpler digital scanner methodology is built for speed. Although the setting time for the solution means one set of grooves could be analyzed in 15 minutes, it's expected 20 clubheads could be analyzed in half an hour or less (because multiple clubs can be done at the same time.) The PGA Tour invited USGA officials to recent tour events in New Jersey, Boston and Chicago to show players how grooves were being measured and to educate them on what clubs in their current sets might not meet the new groove size stipulations.

While the rule is scheduled to go into effect on the PGA Tour in 2010 and for all participants at all levels of qualifying for the U.S. Open, U.S. Women's Open and U.S. Senior Open, most manufacturers believe they will have product ready for elite players this fall. Many manufacturers are likely to use this portable method to check the manufacture of the grooves in new wedges and irons since the new rule applies to all irons and wedges submitted for conformance starting in 2010. The USGA is expected to produce a list of clubs that already conform to the new rule sometime later this month.